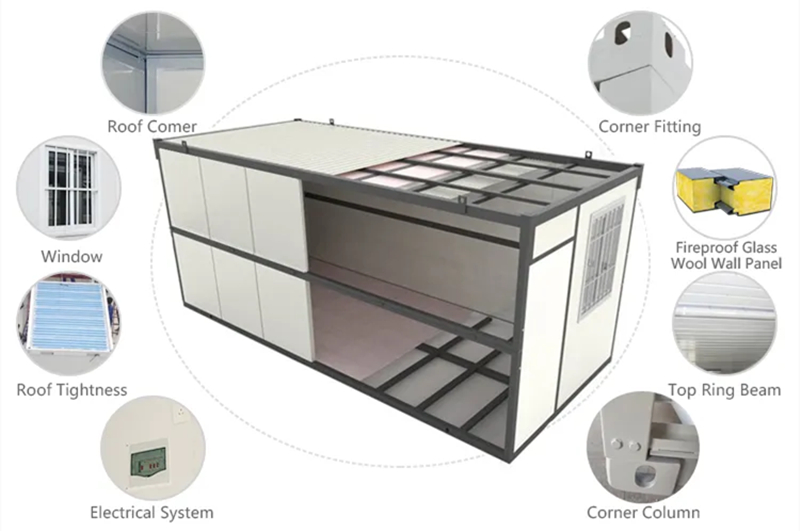

Whether it is a 20-foot or 40-foot folding container house, they all have the characteristics of quick construction, easy transportation and reusability. They can be prefabricated and assembled in a factory, and then shipped folded for quick erection at their destination. At the same time, they can also be combined and expanded as needed to suit different venues and needs.

These folding container houses all need to consider structural stability, windproof and waterproof, thermal insulation, ventilation and other factors to ensure comfort and safety. In addition, relevant building codes and environmental regulations need to be complied with to ensure the legality and environmental friendliness of the building.

In short, 20-foot and 40-foot folding container houses are flexible and convenient temporary building solutions that can meet the needs of various temporary residences and office spaces. They play an important role in applications such as disaster relief, field work sites, and exhibitions.

Item No :

FC13Order(MOQ) :

5Payment :

Telegraphic TransferProduct Origin :

ChinaColor :

CustomizedShipping Port :

Guangzhou/Shenzhen/FoshanLead Time :

3-15Customized Design Creative Prefab Portable Fold Out 20ft 40ft Container House For Sale

20-foot and 40-foot folding container houses are two common specifications, they have similar characteristics and uses based on the size of the container, but the size is slightly different.

The 20-foot folding container house is based on the standard 20-foot container size (about 6 meters long), which is folded and assembled to form a complete house unit. This kind of housing is usually suitable for temporary residences, mobile offices, field site dormitories and other places. It is relatively small and suitable for individual or small group use.

The 40-foot folding container house is based on the standard 40-foot container size (about 12 meters long), which is also folded and assembled to form a complete house unit. This kind of housing is usually suitable for larger-scale temporary residences, office spaces, exhibition halls, etc., and can accommodate more people and facilities.

Product Specification

|

Configuration - Standard Folding Container |

||

|

Specification |

external dimension (mm) |

5800*2480*2560 |

|

Internal dimension (mm) |

5640*2320*2420 |

|

|

Package dimension (mm) |

5800*2480*410 |

|

|

Weight |

≈1300KG |

|

|

Index |

Structural Design Service Life |

10 years |

|

ground live load |

200kg/㎡ |

|

|

roof live load |

100kg/㎡ |

|

|

wind load |

Grade 8 |

|

|

Seismic Fortification Intensity |

Grade 10 |

|

|

Main structure |

Top frame |

Main beam Q235B rectangular square tube |

|

Secondary beam Q235B rectangular square tube |

||

|

Secondary beam Q235B rectangular square tube |

||

|

Bottom frame |

Main beam Q235B rectangular square tube |

|

|

Main beam Q235B rectangular square tube |

||

|

Secondary beam Q235B rectangular square tube |

||

|

side |

Main beam Q235B galvanized P-type pipe |

|

|

front and back |

Main beam Q235B galvanized P-type pipe |

|

|

corner |

Q235B thickness 8mm |

|

|

folding hinge |

Galvanized hinge, high strength |

|

|

Roof |

Integral frame protective coating |

Electrostatic spray/straight white plastic powder |

|

external roof |

Galvanized sheet |

|

|

interior ceiling |

Color steel veneer V831,0.37mm |

|

|

Wall panel |

Insulation glass wool |

glass wool roll 50mm |

|

side wall |

0.3/0.3 75mm Thick glass wool composite board |

|

|

Front and rear wall panels |

0.3/0.3 75mm Thick glass wool composite board |

|

|

Floor |

cement mix floor 15mm |

|

|

Electrical System |

Electrical wiring is installed in strict accordance with moisture-proof specifications, and all electrical products meet CE certification. Connect the circuit according to the circuit engineering specification, indoor: 4² national standard annealed copper wire, 1 32A circuit breaker, 1 three-hole air-conditioning socket, 2.5² socket incoming line, 1 five-hole single-open socket, 1 five-hole socket, 1 LED light |

|

|

door |

High quality anti-theft door (warm white) size: 860mm*1990mm |

|

|

window |

920*920 single glass sliding window plastic steel window with guardrail screen window, glass thickness 4mm |

|

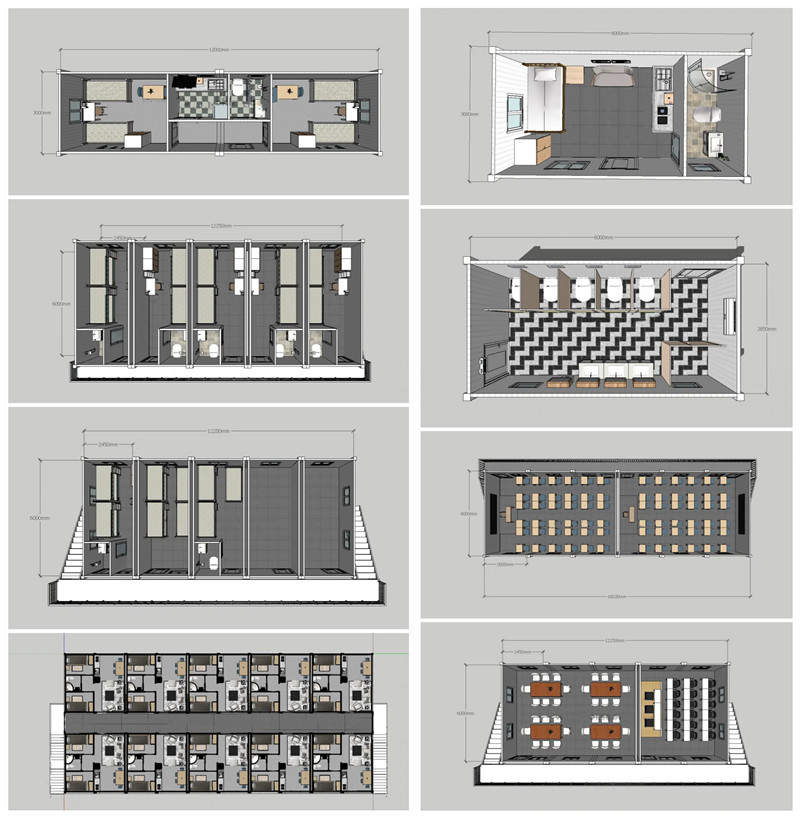

Interior design

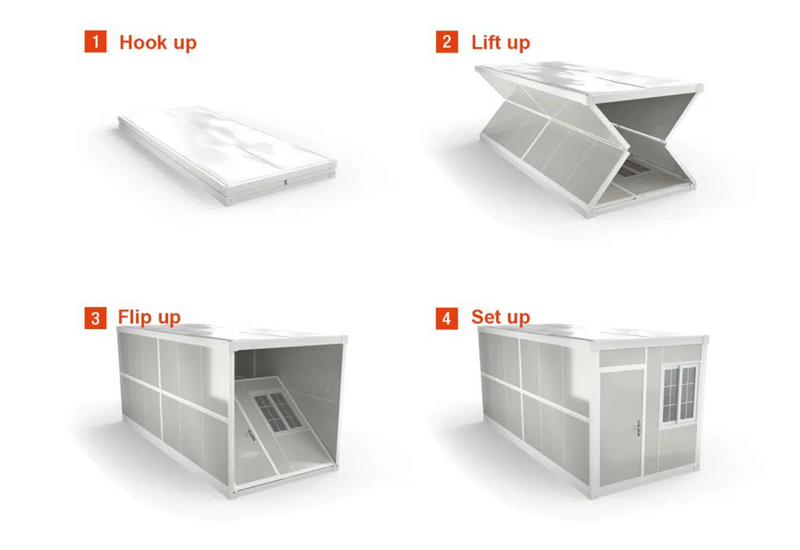

product installation

The production and assembly of all the components of the folding container house are prefabricated at the factory. You can install the Folding House on the job site in just four steps.

1. Use the crane to live its roof. Lift its roof slowly until the house is unfolded and stop the crane there.

2. Expand the front and back walls of the container. Push the front and back from inside, and make it stand in the correct place.

3. Use the bolts to fix the whole structure. There will be premade bolt holes on the columns, and we will provide enough bolts for you to fix them.

4. Install the door lock. To prevent the door lock from damaging the ceiling during the folding process, we will not install the door lock in advance. If you need to move the house to another place and need to fold it, please remember to take down the door lock in advance also.

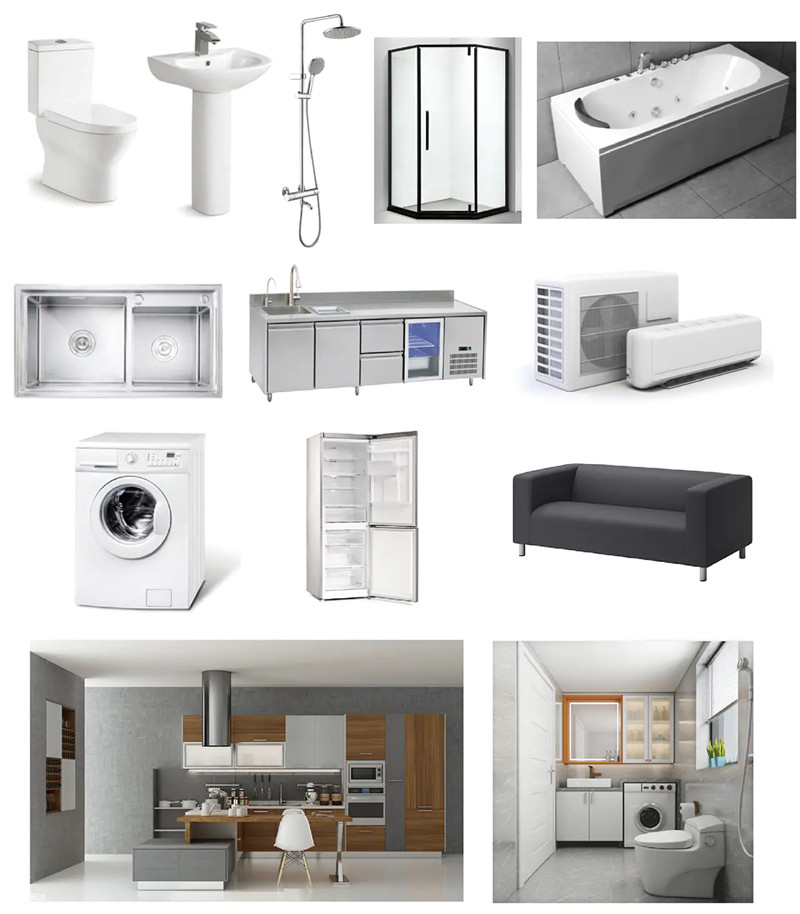

Supporting Facilities

Tags :

Hi! Click one of our members below to chat on